Did you ever attempt to bend or even break a cardboard stick but unfortunately didn’t make it because it was simply too thick? Then, you likely leant it up against a wall, stepped on it with great force, and broke it. Stress alone is what causes it to break is shear stress.

Shearing stress is the force’s magnitude per unit area perpendicular to the member’s axial. When you firmly stood on the cardboard stick, two different types of stresses were produced:

- Flexural stress, also known as bending stress, runs parallel to the member’s axial direction.

- Shear stress runs perpendicular to the member’s axial direction.

What is Shearing Stress?

Shearing stress definition: Shear stress is a force that breaks the structures and takes place along one or more planes. Shear stress is most often associated with the study of physics, but it is also occasionally employed in other fields like engineering or geology. Instances of shear stress are felt by construction materials for engineering or on a steep hill or mountain that might slide, resulting in a landslide, for geology.

Although shear stress is a force within itself, it can also be seen as a collection of forces. Shear stress, for instance, can result from a combination of factors, such as gravity drawing down items on the slope, loss of frictional resistance from sand grains or rocks, or lifting heavy items on the slope.

Examples of Shearing Stress

In actuality, whenever you cut or break something, you are transferring shear stress. Other instances of shear stress are force exerted on a pipeline by fluid in motion. Shear stress makes a sand castle fall when someone walks on it rather than just resting. Geotechnical engineers consider soil shear stress when building a structure’s foundation to prevent failure due to shear.

When a pair of scissors is employed to cut a piece of paper, the two sections apply lateral stresses that put the member (paper) under shear stress, allowing the paper to cut.

Shearing Stress Formula

The normal stress formula can be stated as follows:

τ = F / A

where:

τ = shear stress (expressed in pascals or N/m²)

F = shear force (expressed in N)

A = area (expressed in m²)

Shear Stress Units

As stated, shear stress is measured in Pascals or Newtons per square metre (N/m²).

- One Pascal is equivalent to one N/m².

- A Newton is an analysis of the force required to move a kilogramme (kg) one metre (m) per second (s) per second.

- The Pascals or Newtons per square metre (N/m²), shear stress units, represent the force required to move one kilogramme of material per second over a specific area (m2). Shear stress units measure how much force must be applied to a particular slope location for the slope to collapse and slide downward.

What is Maximum Shear Stress?

The maximum shear stress is the amount of shear force produced in a relatively compact space. Shear stress occurs all through the structural component experienced when an external force acts in a direction that is opposed to and out of alignment with internal forces. These forces will be of varying magnitudes.

The distinct cross-sections of the structural member won’t be distributed equally across the entire member. These forces subject the structural material to shear stress. Based on the maximum shear stress theory, the maximum shear stress that a material can withstand is concentrated in just a few small places of the member.

Maximum Shear Stress Formula

The maximum shear stress formula will determine the maximum shear stress. Thus, to evaluate the shear stress, the first step is obtaining the maximum shear stress formula.

This equation will lead to the expression for the maximum shear stress. The following figures will be required for the computation of a rectangular cross-section of a beam:

h = Height of the cross-section

b = Width or breadth of the cross-section

V = Shear force in the cross-section

Q = A x Y = First moment of area

A = Section’s area above the desired plane

y = Distance between the area’s centroid and neutral axis

I = Total section’s moment of inertia related to the centroid

I (rectangular section) = h x b

Types of Shearing Stress

There are various types of shear stress. Each type of shear stress explains the force exerted on a material or object in multiple directions. Following are some of the types of shear stress discussed below:

Transverse Shearing Stress

An object is subjected to transverse shear when perpendicular stress is applied to the object’s longitudinal axial’s direction. Think about a long pole that is connected at one end only. If force is exerted to the end of the pole where it has no support, the transverse shear stress would be imposed perpendicular to the length of the pole, allowing it to bend at the end where it is not attached. Because a force is exerted in a single direction, transverse shear stress differs from torsional shear stress.

Torsional Shearing Stress

Torsional shear stress results from torsion, which occurs when equal forces are exerted on an object in opposing directions. Think of someone rolling a pencil between their palms. One would need to exert force with one palm drifting away from the pencil from their body and with the other palm dragging that pencil toward their body to make it roll. The pencil will spin due to these forces since torque is being imparted to it. If an item is linked at one end, it will twist rather than roll.

Beam Shearing Stress

Beam shear stress results when a beam is subjected to force that is not applied consistently. This shear stress is distinct from others because it is transmitted to a beam and not other objects. The calculation is as follows:

τ avg = V / A

Where:

τ = avg shear stress averaged at the cross-section

A = cross-sectional area

V = shear stress at the cross-section

Wall Shearing Stress

The pressure a fluid exerts against a wall is known as wall shear stress. Wall shear stress is a notion that may be used to describe blood circulation in veins and arteries as well as fluid flow in pipelines. Wall shear stress can be measured using either direct or indirect methods.

Direct techniques include film-based approaches and floating element sensors, which directly detect the wall shear stress. As opposed to being a direct measurement, indirect procedures associate shear stress with other quantities to infer shear stress.

Shearing Stress in Fluids

Shear stress can also be seen in fluids. Shear stress and the point of contact between the fluid and the boundary can both be seen when a fluid is moving within the boundary of solids.

Fluid is made up of many levels that move at various speeds. The speed of the layers will be the same regardless of their distance from the boundary. Shear stress is mostly to blame for this variable speed between the strata.

Next, stress and strain have various relationships in fluids. In other words, we understand that shearing stress is dependent on strain rate and is proportionally constant to viscosity over here

Shearing Stress in the Real World

From the minute you wake up and get out of bed till you fall back asleep. Almost all daily activities include some level of shear stress. Here are a few examples of similar real-world events:

- Chopping and cutting activities (Cutting vegetables, fruits, paper, wood, clothes etc.)

- Brushing, colouring, applying creams, lotions, soaps, etc.

- Chewing or breaking down food into smaller pieces from teeth.

- While moving forward, either running or walking, our feet push the ground back.

- Experiencing shear stress when a moving vehicle starts or stops.

- River beds are stressed by shear when water flows, thereby causing erosion.

Conclusion

Shear means “to cut off.” When a force acts over a hard object’s surface area (in a parallel direction to the surface), the force will separate one section of the object from the other.

As a result, deforming the object, which causes strain (shear strain- the angular deflection of the object from its original position). In addition, the object’s stiffness makes it resistant to deformation, and Newton’s third law of motion predicts the emergence of a restoring force along the object’s surface.

The object’s restoring force will likely work against the applied force’s shearing effect. Therefore, shear stress is essential for the result of shear strain.

Frequently Asked Questions

1. Shearing stress definition.

Ans. Shearing stress is a type of stress that acts parallel to the material’s cross-section. It arises because of shear forces. It is the combination of forces that exert equal but opposing pressure on the two sides of a body.

2. Explain the process of shearing stress with illustrations.

Ans. Here are certain illustrations of shear stress:

- Shear stress is experienced when you chew food between your teeth.

- When a speeding vehicle starts or stops, the seat’s surface experiences shear stress.

- Similarly, your feet push the ground backwards when you walk or run.

3. What distinguishes tensile stress from shear stress?

Ans. Shear and tensile stress are two separate types of stress where force is differently imparted to an object. When a high deforming force is exerted on a surface at an angle, it causes tensile stress. On the other hand, shear stress results from a deforming force being exerted parallel to the surface.

Relevant Articles

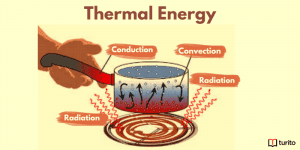

Understanding Thermal Energy: What It Is and How It Works

Thermal energy is essential to our daily lives, from warming …

Understanding Thermal Energy: What It Is and How It Works Read More »

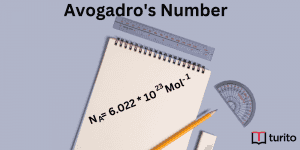

Read More >>Avogadro’s Number: Meaning, Importance, and More

Introduction The concept of measuring the microscopic particles that make …

Avogadro’s Number: Meaning, Importance, and More Read More »

Read More >>Kinetic Friction – Definition, Laws, Types

Kinetic Friction Kinetic force is a force acting between two …

Kinetic Friction – Definition, Laws, Types Read More »

Read More >>

Comments: